Drum Dumper Market: Industrial Material Handling Equipment, Workplace Safety and Ergonomics, and Hydraulic and Electric System Trends

The Global Drum Dumper Market is a vital segment of the industrial material handling equipment industry. Drum dumpers (also known as drum tippers or rotators) are mechanical devices designed to lift, rotate, and empty various types of drums—steel, plastic, or fiber—into tanks, hoppers, or mixers. As manufacturing and processing industries move toward higher levels of automation and stricter workplace safety standards, these machines have become essential for efficient and injury-free operations.

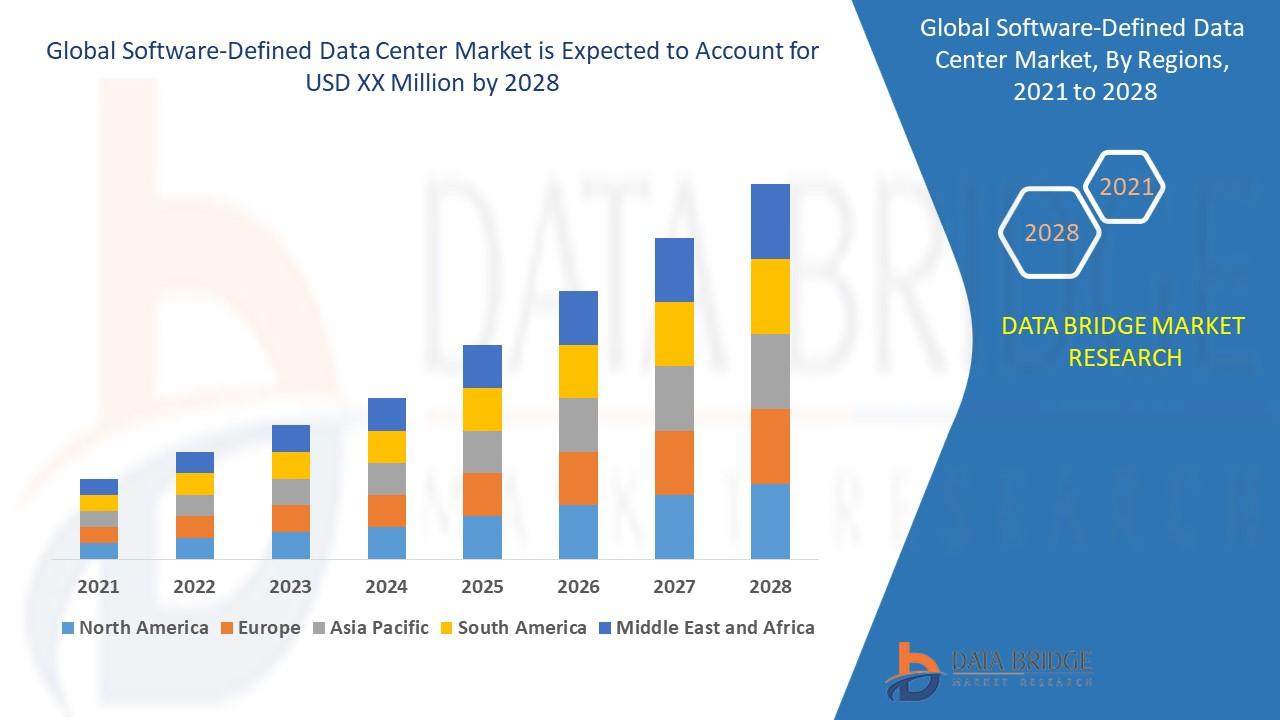

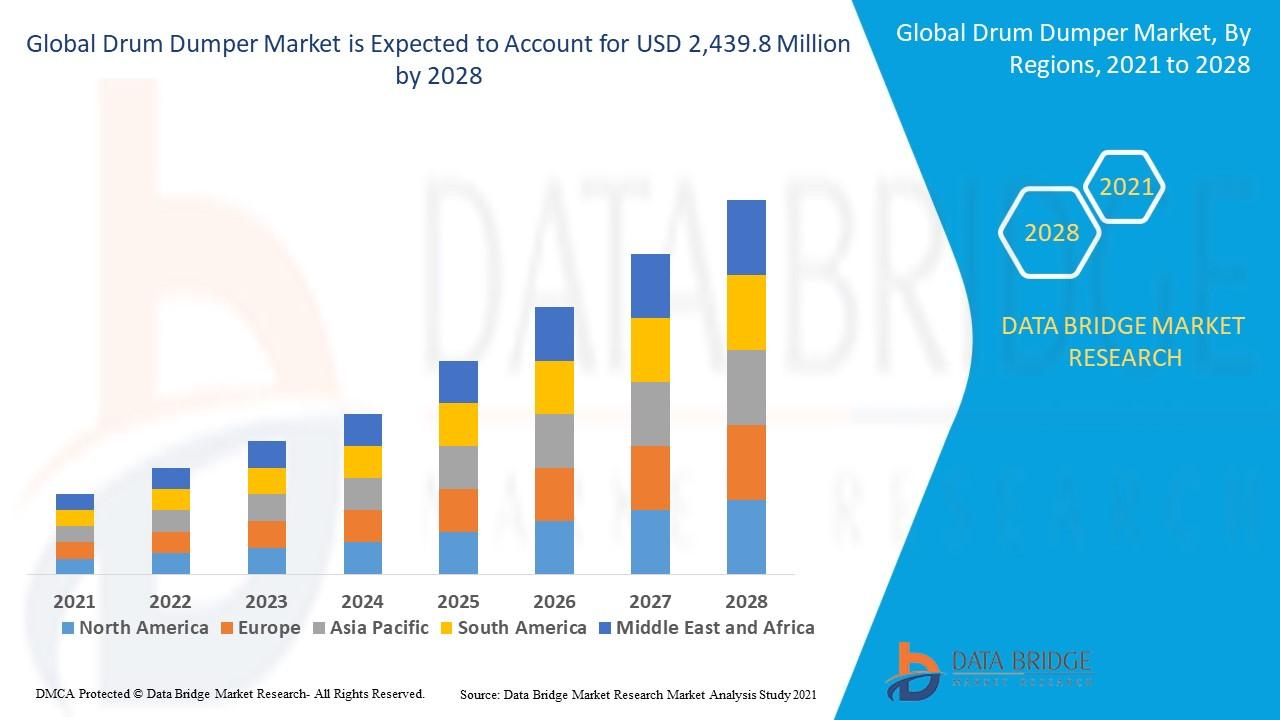

Drum dumper market is expected to gain market growth in the forecast period of 2021 to 2028. Data Bridge Market Research analyses the drum dumper market to reach at an estimated value of USD 2,439.8 million by 2028 and exhibit a CAGR of 6.70% for the forecast period of 2021-2028.

Market Size and Growth Outlook

The market is currently on a robust growth trajectory, valued at approximately USD 2.31 billion in 2025. It is projected to reach approximately USD 3.72 billion to USD 3.94 billion by 2032–2035, exhibiting a healthy Compound Annual Growth Rate (CAGR) between $5.09\%$ and $7.02\%$. This expansion reflects a global shift toward mechanized lifting solutions to replace high-risk manual labor.

Key Drivers Fueling Market Demand

The expansion of the drum dumper market is underpinned by several industrial and regulatory factors:

-

Stringent Workplace Safety Regulations: Occupational health and safety agencies globally (such as OSHA in the US and EU-OSHA in Europe) are enforcing stricter rules to reduce musculoskeletal injuries caused by manual lifting. Drum dumpers provide a mechanized alternative that virtually eliminates the risk of back injuries and spills.

-

Industrial Automation & Industry 4.0: The push for "smart" manufacturing is integrating drum dumpers with automated production lines. Advanced models now feature programmable controls and sensors, allowing them to integrate seamlessly with Warehouse Management Systems (WMS).

-

Handling of Hazardous Materials: In sectors like specialty chemicals and petroleum, the safe decanting of volatile or toxic substances is critical. Specialty explosion-proof (ATEX-certified) drum dumpers are in high demand for these high-risk environments.

-

Rapid Growth in Emerging Economies: Massive industrialization in the Asia-Pacific region, particularly in India, China, and Vietnam, is creating a surge in demand for basic and advanced material handling equipment to support new chemical and food processing plants.

https://www.databridgemarketresearch.com/reports/global-drum-dumper-market

Market Segmentation: Technology and Application

The market is segmented by power source, portability, and end-use to meet specific operational requirements:

By Product Type & Power Source:

-

Hydraulic Drum Dumpers (Dominant Share): These hold roughly $40\%$ to $80\%$ of the market share (depending on the region) due to their high load capacity, smooth operation, and relatively low maintenance requirements.

-

Electric/Battery-Powered: The fastest-growing segment in clean-room environments (like pharmaceuticals) where hydraulic fluids could pose a contamination risk.

-

Portable vs. Stationary: Portable drum dumpers captured a significant share (around $53\%$ in 2024) due to their operational flexibility, allowing them to be moved across different production lines.

By End-Use Industry:

-

Oil and Lubricants (Largest Segment): Holds approximately $28\%$ of the market share, driven by the global demand for crude oil derivatives and the heavy nature of lubricant barrels.

-

Food & Beverages: Increasingly adopting stainless-steel, wash-down compatible dumpers to maintain hygiene standards while handling bulk ingredients.

-

Pharmaceuticals: Utilizing high-precision dumpers with specialized clamps for clean, dust-free material transfer.

Regional Market Dynamics

-

North America: Currently the market leader, supported by an advanced pharmaceutical sector and a high degree of technological adoption in the food processing industry.

-

Asia-Pacific: The fastest-growing regional market. Increasing manufacturing infrastructure and a large-scale move toward automated warehouses in China and India are the primary growth catalysts.

-

Europe: Driven by the EU Machinery Directive, which emphasizes the implementation of safe and efficient industrial equipment, particularly in Germany and the UK.

Browse More Reports:

Global Casting and Splinting Market

Global Muckle Wells Syndrome Market

Global Capacitor Bank Controllers Substation Automation Market

Global Metallic Pigments Market

Global Primary Biliary Cirrhosis Market

Global High Purity Specialty Gases Market

Global Merkel Cell Carcinoma Treatment Market

Global Speech Recognition AI (Artificial Intelligence) Camera Market

Global Hosted Telephone Systems Market

Global Fetal and Neonatal Critical Care Equipment Market

North America Busbar Market

Global Carcinoembryonic Antigen (CEA) Market

Global Events Services Market

Global Soda Water Dispenser Market

Global Diesel Bottled (Aftermarket) Fuel Additives Market

Conclusion

The Global Drum Dumper Market is evolving from simple mechanical tilters into sophisticated, automated components of the modern industrial ecosystem. While the initial investment cost remains a barrier for some small-scale enterprises, the long-term benefits of reduced labor costs, improved worker safety, and minimized material wastage provide a compelling return on investment. The future of this market lies in the integration of IoT for real-time monitoring and the development of fully autonomous robotic dumpers that can navigate warehouse floors and execute complex pouring tasks without human intervention, further solidifying the drum dumper’s role as an indispensable tool for safe and efficient global production.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com