Conformal Coatings Market: PCB Protection Technology, Applications in Consumer Electronics and Automotive, and Material Science Innovations

The Global Conformal Coatings Market is a critical subset of the electronics and specialty chemicals industries. Conformal coatings are thin polymeric layers—typically measured in micrometers—applied directly to printed circuit boards (PCBs) and electronic components. Their primary function is to "conform" to the irregular landscape of the board, providing a protective barrier against moisture, dust, salt spray, chemical contaminants, and thermal extremes.

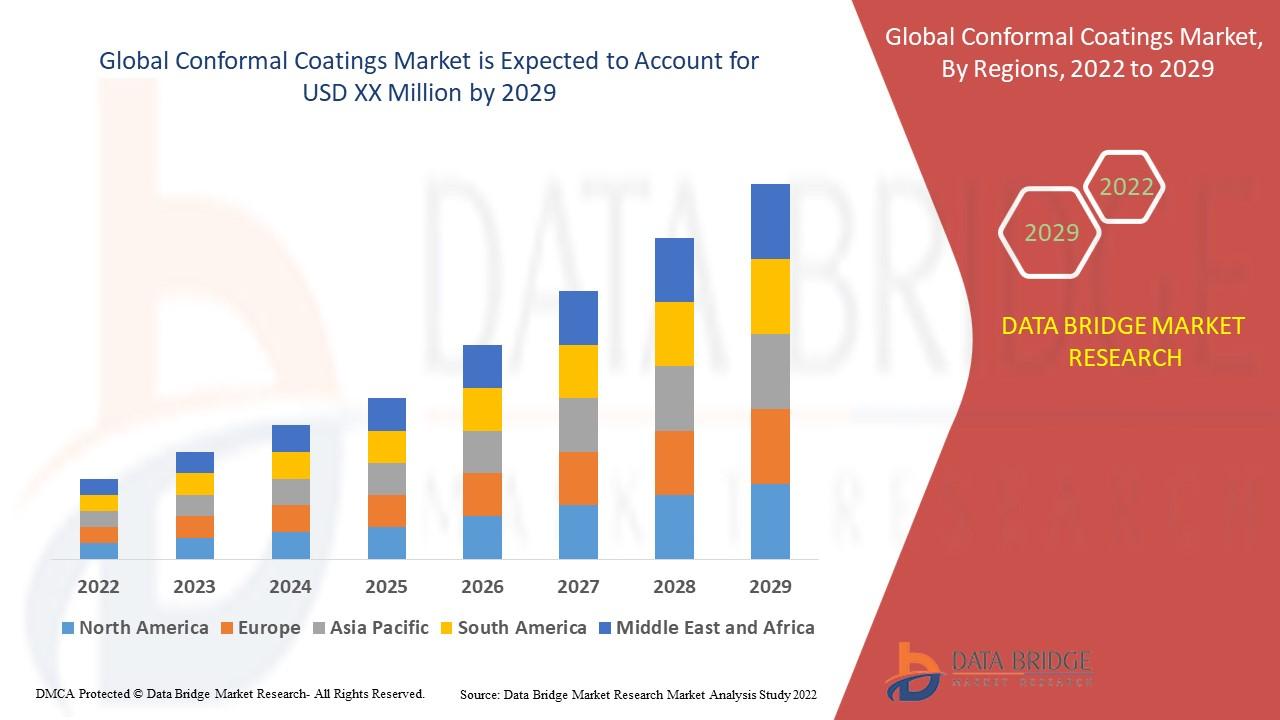

The conformal coatings market is expected to witness market growth at a rate of 4.5% in the forecast period of 2022 to 2029.

Market Size and Strategic Growth

As of late 2025, the global conformal coatings market is valued at approximately USD 1.5 billion, though some broader industry estimates including equipment and secondary materials range as high as USD 13.5 billion to USD 15.2 billion. The market is projected to expand at a Compound Annual Growth Rate (CAGR) of 5.5% to 6.2% through 2030–2035.

This steady expansion is driven by the "electronics-everywhere" trend, where sensitive circuitry is being deployed in increasingly hostile environments, from under-the-hood automotive sensors to deep-sea telecommunications equipment and wearable medical devices.

Core Market Drivers

The growth of the conformal coatings sector is fundamentally linked to the complexity and miniaturization of modern technology:

-

Automotive Electrification (EVs) and ADAS: Modern electric vehicles (EVs) and Autonomous Driving Assistance Systems (ADAS) rely on an unprecedented density of electronics. These components must withstand extreme vibrations, road salts, and thermal cycling, making high-performance coatings like silicones and urethanes non-negotiable.

-

5G Infrastructure and Telecommunications: The global rollout of 5G necessitates millions of new base stations and outdoor hardware. These units are exposed to the elements 24/7, driving a surge in demand for moisture-resistant and thermally stable coatings.

-

Miniaturization of Consumer Electronics: As smartphones, tablets, and IoT devices become smaller, the distance between conductive traces on a PCB decreases. This increases the risk of "dendritic growth" and short-circuiting due to humidity, necessitating thinner, more precise coating applications.

-

Medical and Life Sciences: Conformal coatings are increasingly used in implantable devices like pacemakers and neurostimulators, as well as diagnostic equipment, where biocompatibility and pinhole-free protection are vital.

https://www.databridgemarketresearch.com/reports/global-conformal-coatings-market

Market Segmentation: Materials and Technology

The market is highly diversified based on the chemical properties required for specific environments:

By Material Type:

-

Acrylic (Largest Market Share): Occupies approximately 44% of the market. Acrylics are favored for their cost-effectiveness, ease of application, and the ability to be easily "reworked" or repaired.

-

Silicone: Preferred for high-temperature applications (up to 200°C) and environments requiring flexibility to absorb mechanical shock.

-

Polyurethane (Urethane): Known for superior chemical and abrasion resistance, making them ideal for heavy industrial and aerospace applications.

-

Parylene (Fastest Growing Niche): Applied via Chemical Vapor Deposition (CVD), Parylene provides the thinnest, most uniform protection and is the gold standard for medical and aerospace mission-critical hardware.

By Curing Technology:

-

Solvent-Based: The traditional standard, though facing pressure due to environmental regulations.

-

UV-Curable (Fastest Growing Technology): Driven by the need for high-speed production. UV-cured coatings dry in seconds under specialized lamps, significantly reducing factory cycle times and eliminating Volatile Organic Compound (VOC) emissions.

Regional Insights

-

Asia-Pacific (Market Leader): Dominates with over 42% to 50% of the global share. This region is the global hub for PCB manufacturing, with China, Taiwan, Japan, and South Korea leading the production of consumer electronics and automotive components.

-

North America: The second-largest market, primarily driven by a robust aerospace and defense sector where high-reliability coatings are a mandatory requirement.

-

Europe: A key region for innovation, particularly in Germany, where the focus on high-end automotive engineering and green (VOC-free) coating technologies is highest.

Browse More Reports:

Global Casting and Splinting Market

Global Muckle Wells Syndrome Market

Global Capacitor Bank Controllers Substation Automation Market

Global Metallic Pigments Market

Global Primary Biliary Cirrhosis Market

Global High Purity Specialty Gases Market

Global Merkel Cell Carcinoma Treatment Market

Global Speech Recognition AI (Artificial Intelligence) Camera Market

Global Hosted Telephone Systems Market

Global Fetal and Neonatal Critical Care Equipment Market

North America Busbar Market

Global Carcinoembryonic Antigen (CEA) Market

Global Events Services Market

Global Soda Water Dispenser Market

Global Diesel Bottled (Aftermarket) Fuel Additives Market

Conclusion

The Global Conformal Coatings Market is transitioning from a traditional chemical-supply industry into a high-precision technology enabler. The future of the market lies in the development of bio-based, eco-friendly coatings that comply with tightening global environmental standards (such as REACH and RoHS) without sacrificing performance. Additionally, the integration of AI-driven robotic dispensing systems is allowing manufacturers to apply these coatings with micrometer precision, reducing waste and ensuring the reliability of the next generation of smart, connected devices. In a world where electronic failure can mean the loss of critical data or even life, conformal coatings remain the silent, essential guardians of the digital age.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com