Global Additive Manufacturing Market Forecast to 2031: Innovation, Sustainability, and Regional Growth Opportunities

The additive manufacturing industry, often referred to as 3D printing, is rapidly evolving into a cornerstone of modern industrial production. From plastics and metals to ceramics and advanced composites, additive manufacturing technologies are reshaping how industries design, prototype, and manufacture products.

Recent industry developments underscore how additive manufacturing is no longer confined to prototyping—it is now a full‑scale production enabler. At the Formnext 2025 Expo in Frankfurt, leading innovators showcased breakthroughs in selective laser sintering (SLS), stereolithography (SLA), and fused deposition modeling (FDM), highlighting how automation, sustainability, and digital integration are driving the next wave of growth.

Why Additive Manufacturing Matters

Additive manufacturing is revolutionizing industries by offering design freedom, reduced waste, and faster production cycles. Unlike traditional subtractive methods, it builds products layer by layer, enabling lightweight structures, complex geometries, and customized solutions. This technology is particularly vital in aerospace, automotive, healthcare, and industrial manufacturing, where efficiency and precision are paramount.

Market Highlights (Forecast to 2031)

-

Market Size & Share: Additive manufacturing is expected to sustain strong growth, driven by adoption across automotive, aerospace, healthcare, and industrial sectors.

-

Trends:

-

Rising use of metal 3D printing for aerospace and defense applications.

-

Increased demand for biocompatible materials in healthcare, particularly for implants and prosthetics.

-

Expansion of ceramic additive manufacturing for high‑temperature industrial applications.

-

-

Analysis:

-

Automotive manufacturers are leveraging additive manufacturing for lightweight components and rapid prototyping.

-

Aerospace companies are integrating 3D printing into supply chains to reduce costs and improve fuel efficiency.

-

Healthcare is emerging as a key growth sector, with patient‑specific solutions driving adoption.

-

-

Forecast:

-

By 2031, additive manufacturing will be deeply integrated into smart factories, with AI and automation enhancing scalability and sustainability.

-

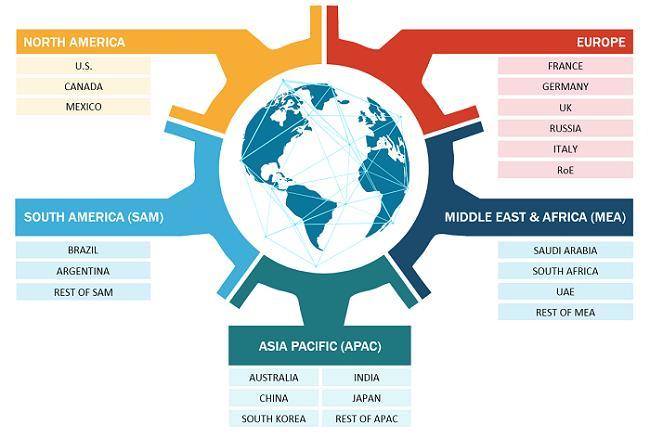

Global and Regional Insights

-

North America: A leader in additive manufacturing innovation, driven by aerospace and defense investments.

-

Europe: Strong focus on sustainability and circular economy principles, with major hubs in Germany, France, and the UK.

-

Asia‑Pacific: The fastest‑growing region, fueled by expanding automotive and healthcare industries, alongside government support for advanced manufacturing.

-

Latin America & Middle East: Emerging opportunities in industrial manufacturing and defense, supported by modernization initiatives.

Updated Industry News

-

Sustainability in Manufacturing: New regulations in 2026 are encouraging manufacturers to adopt additive technologies that reduce waste and energy consumption.

-

Healthcare Breakthroughs: Hospitals are increasingly using 3D printing for surgical planning, prosthetics, and bioprinting research.

-

Industrial Integration: Smart factories are embedding additive manufacturing into production lines, enabling mass customization and reducing lead times.