Tungsten Carbide Powder Industry Accelerates with Innovation, Sustainability, and Growing Global Demand

The Tungsten Carbide Powder industry is experiencing a period of heightened activity and strategic transformation, driven by expanding applications, supply chain dynamics, and advancements in material science. As a cornerstone material in wear-resistant tooling and precision industrial components, tungsten carbide powder continues to gain recognition across manufacturing, construction, aerospace, automotive, and technology sectors — reinforcing its role as a foundational material for modern industry.

Request Sample Pages of this Research Study at – https://www.theinsightpartners.com/sample/TIPRE00009086/

Tungsten Carbide Powder Market Segmentation

Grade

- Rotary Drilling and Mining

- Metal Forming and Wear

- Submicron

- Corrosion Resistant

- General Purpose

Application

- Machine Tools and Components

- Cutting Tools

- Dies and Punches

- Abrasive Products

End Use Industry

- Mining and Construction

- Industrial Engineering

- Transportation

- Oil and Gas

- Aerospace and Defense

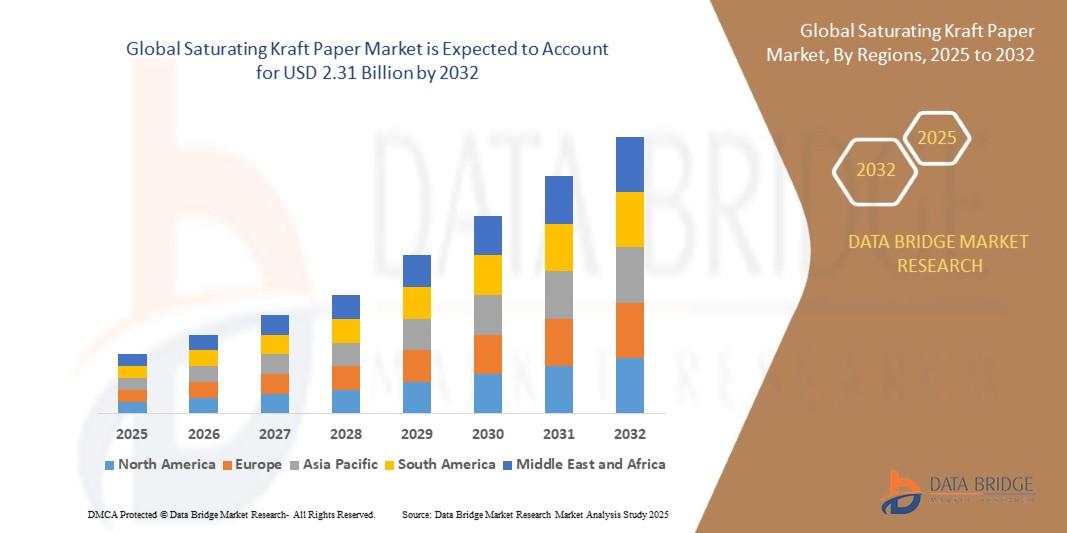

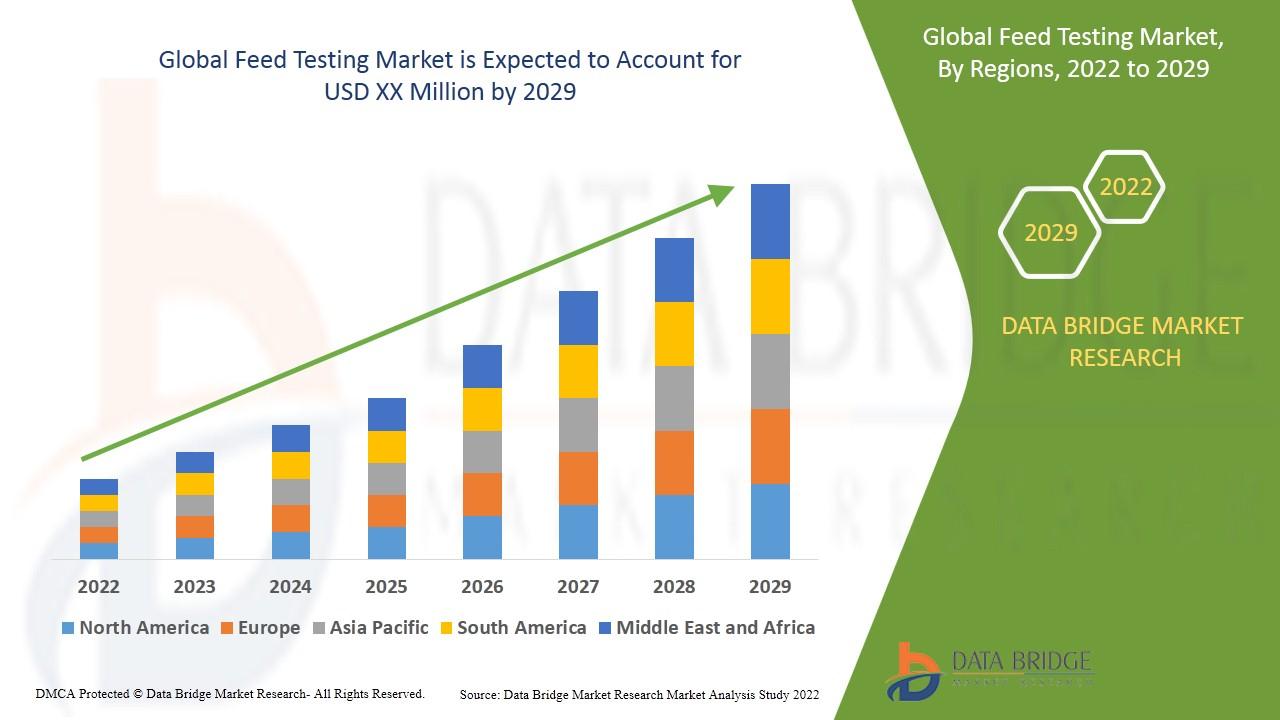

Geography

- North America

- Europe

- Asia-Pacific

- South and Central America

- Middle East and Africa

Market leaders and key company profiles

· Sandvik AB

· Kennametal Inc

· Ceratizit SA

· Lineage Alloys Inc

· Federal Carbide Co

· Guangdong Xianglu Tungsten Co Ltd

· Nanchang Cemented Carbide Co Ltd

· Japan New Metal Co Ltd

· Buffalo Tungsten Inc

Market Dynamics and Industry Trends

Tungsten carbide powder is prized for its exceptional hardness, superior wear resistance, and thermal stability, making it indispensable in high-performance applications where durability and precision are essential. Its unique properties — often described as “diamond-like” in hardness and toughness — enable manufacturers to design cutting tools, wear parts, and specialized components across a broad range of sectors.

Recent industry reporting underscores ongoing price volatility and supply adjustments across tungsten and its derivative materials. Tightness in tungsten concentrate supply has contributed to sustained price movements and impacted production cycles across upstream and downstream segments of the value chain.

Expanding Industrial Applications

Across end-use industries, tungsten carbide powder is increasingly leveraged to enhance performance and longevity. In metalworking, it forms the backbone of high-precision cutting tools and dies that outperform traditional materials under demanding conditions. In mining and construction, carbide-based tooling significantly extends service life in drilling and excavation equipment — reducing downtime and maintenance costs.

The aerospace and defense sectors also continue to adopt tungsten carbide-based components for engine parts, landing gear systems, and structural elements exposed to extreme temperatures and mechanical stress. Similarly, automotive manufacturers benefit from tungsten carbide’s wear resistance in engine components and cutting tools, improving fuel efficiency and performance.

Emerging technological ecosystems — such as additive manufacturing — are further elevating the importance of tungsten carbide powder. Its integration into 3D printing and advanced fabrication workflows enables the creation of complex geometries and specialized tooling that were previously difficult or cost-prohibitive to manufacture.

Innovation and Material Advancements

Innovation across powder metallurgy continues to propel the industry forward. Advances in particle size optimization, binder technologies, and sintering techniques are improving the performance characteristics of tungsten carbide powders. These advancements enable better wear resistance, higher dimensional stability, and tailored properties for specific industrial challenges.

Leading materials producers are also exploring novel binder systems — including alternatives to traditional cobalt matrices — to meet sustainability objectives and reduce dependence on critical raw materials. For example, nickel and iron-based binders along with hybrid ceramic matrices are emerging as viable options in select performance applications, expanding material choices for manufacturers seeking enhanced sustainability profiles without compromising performance.

Access full description of the report- https://www.theinsightpartners.com/reports/tungsten-carbide-powder-market

Sustainability and Recycling Initiatives

Environmental responsibility is increasingly influencing decisions across the supply chain. Sustainability practices — including recycling and secondary recovery of tungsten carbide — are gaining traction, reducing waste and lowering the carbon footprint associated with raw material production. Recycled carbide materials help stabilize supply while supporting circular economy principles.

The integration of recycled sources into tungsten carbide feedstock not only reduces environmental impact but also enhances resource efficiency and long-term supply resilience, which is especially important in an era of dynamic global trade conditions.

Strategic Partnerships and Regional Developments

Industry consolidation and strategic alliances continue to shape the competitive landscape. Partnerships between materials producers, original equipment manufacturers (OEMs), and research institutions are accelerating the co-development of custom carbide solutions that address evolving industrial needs. Collaborative efforts are fostering deeper integration across the supply chain and enabling localized manufacturing capabilities in key regions.

Emerging regional markets are also advancing demand for tungsten carbide powder, supported by industrial growth and infrastructure development initiatives. These trends reflect a broader shift toward diversified production networks and increased regional self-reliance.

Looking Ahead

As global industrial activity evolves, tungsten carbide powder stands as a strategic enabler of innovation, resilience, and performance excellence. Its unmatched combination of hardness and durability ensures that it will remain a vital material across manufacturing, construction, transportation, and technology-driven industries.

Manufacturers and industry participants are encouraged to engage with ongoing research and sustainable practices to maximize the value of tungsten carbide powder — capitalizing on its expanding applications and enduring industrial relevance.

Get Premium Research Report of Tungsten Carbide Powder Market Size and Growth Report by 2031 at- https://www.theinsightpartners.com/buy/TIPRE00009086/

Related Report:

· Thermal Spray Powder Market Growth Opportunities and Top Key Players by 2031

· Bi-Metal Band Saw Market Analysis and Forecast by Size, Share, Growth, Trends 2031

About Us: -

The Insight Partners is a one-stop industry research provider of actionable intelligence. We help our clients in getting solutions to their research requirements through our syndicated and consulting research services. We specialize in industries such as Semiconductor and Electronics, Aerospace and Defense, Automotive and Transportation, Biotechnology, Healthcare IT, Manufacturing and Construction, Medical Devices, Technology, Media and Telecommunications, Chemicals and Materials.

Contact Us:

If you have any queries about this report or if you would like further information, please get in touch with us:

Contact Person: Ankit Mathur

E-mail: ankit.mathur@theinsightpartners.com

Phone: +1-646-491-9876

Also Available in : Korean | German | Japanese | French | Chinese | Italian | Spanish