Global Injection Molding Machine Market Size, Share and Growth Analysis – Industry Trends and Forecast to 2029

The Global Injection Molding Machine Market is a critical component of the manufacturing ecosystem, facilitating the mass production of complex polymer and plastic parts across automotive, electronics, packaging, medical devices, and consumer goods industries. Injection molding machines enable high-precision molding with repeatable quality, making them indispensable in modern industrial production.

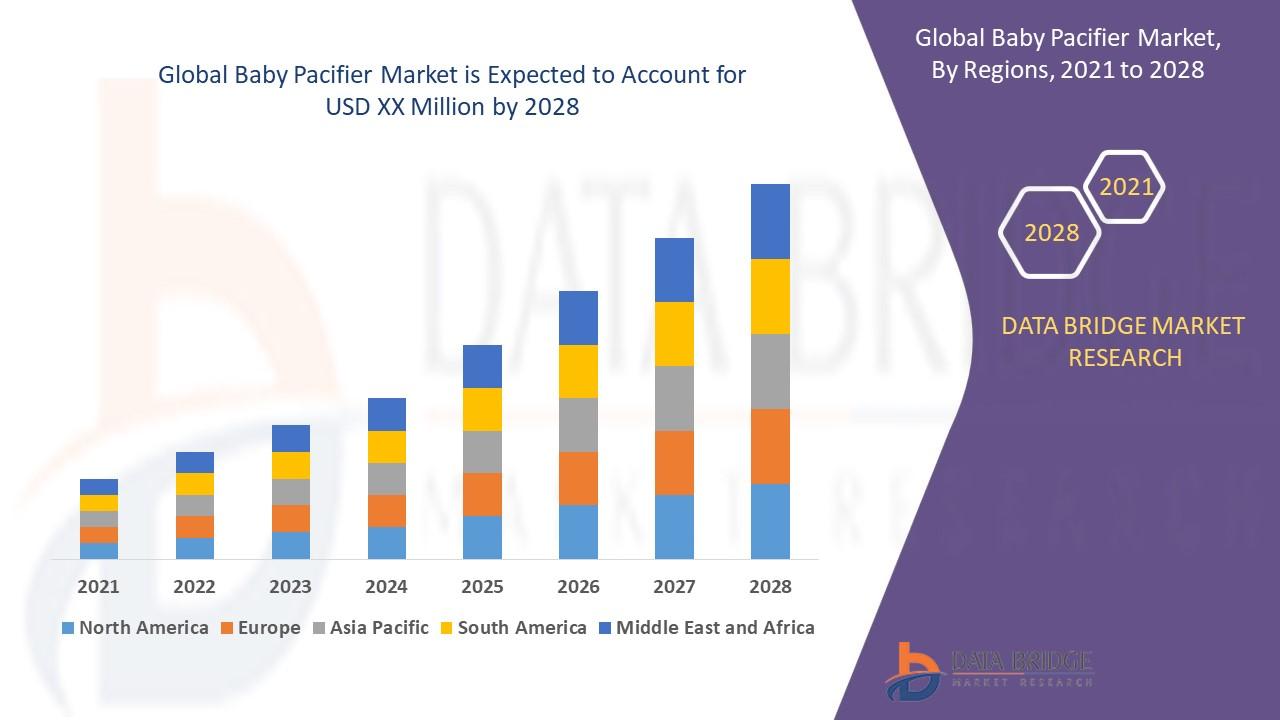

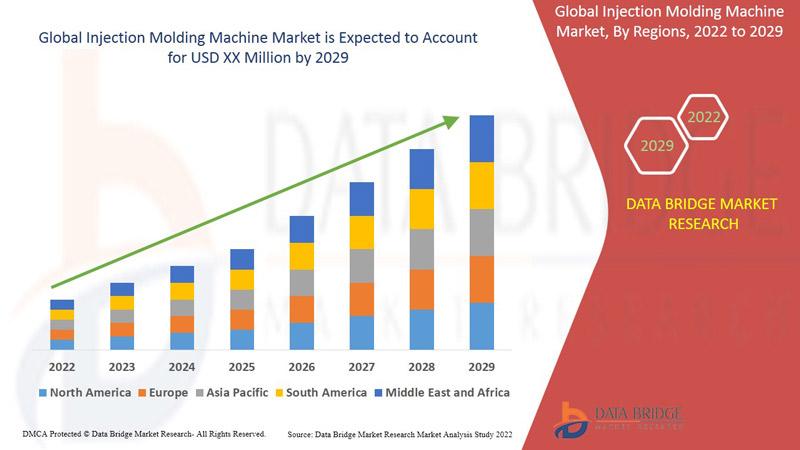

Data Bridge Market Research analyses that the injection molding machine market will witness a CAGR of 5.10% for the forecast period of 2022-2029. Sustained demand for automation, lightweight materials, and precision components continues to propel market expansion globally.

Request a sample of “Global Injection Molding Machine Market” report

@ https://www.databridgemarketresearch.com/request-a-sample?dbmr=global-injection-molding-machine-market

Market Definition

Injection molding machines are industrial capital equipment designed to melt and inject polymer resins into molds under high pressure, producing parts with detailed geometries and consistent dimensional accuracy. Core components include a hopper, heated barrel, reciprocating screw, mold clamping unit, and control systems. These machines are engineered for throughput efficiency, energy optimization, and adaptability to diverse materials such as thermoplastics, thermosets, elastomers, and composites.

Market Drivers

Several key drivers are shaping the global injection molding machine market:

Growth of End-Use Industries: The automotive sector’s push toward lightweight plastic components for fuel efficiency and emissions reduction has accelerated demand for high-speed and precision molding solutions. Similarly, the electronics industry requires intricate plastic housings and assemblies that only advanced injection molding can economically deliver.

Automation and Industry 4.0 Integration: Manufacturers are increasingly investing in automated injection molding cells equipped with robotics, IoT connectivity, and digital controls to improve operational efficiency and reduce labor costs. Industry 4.0 technologies enable predictive maintenance, real-time monitoring, and enhanced production flexibility.

Rapid Expansion of Packaging Sector: Plastic packaging remains a dominant application area due to cost-effectiveness, versatility, and recyclability improvements. Injection molding machines are essential for producing closures, containers, and specialized packaging components in high volumes.

Market Segmentation

The global injection molding machine market is structured to reflect technology variations, clamping force capacity, application areas, and end-use industries:

By Technology: Hydraulic, electric, and hybrid machines. Electric injection molding machines are gaining traction due to energy efficiency and precision control, while hydraulic machines continue to be prevalent for high-tonnage applications.

By Clamping Force: Categories range from small (<100 tons) to large (>1000 tons) capacity machines, enabling scalability for diverse production requirements.

By Application: Automotive components, consumer goods, packaging, medical devices, and electronics, each with specific performance and quality benchmarks.

By End-Use Industry: Automotive, aerospace, healthcare, electronics & electrical, packaging, and home appliances. The automotive and packaging sectors collectively account for a significant proportion of global demand.

Segmentation enables stakeholders to align machine specifications with production goals and industry compliance standards.

Competitive Landscape

The injection molding machine market is competitive and innovation-driven, with global manufacturers investing heavily in automation, energy optimization, and customization. Key market participants differentiate themselves through advanced motion control systems, reduced cycle times, and modular machine architectures that support flexible manufacturing.

Strategic partnerships with materials suppliers, robotics providers, and digital solutions firms are increasingly shaping competitive advantage. Manufacturers emphasizing service networks, spare parts availability, and localized technical support tend to enjoy stronger customer loyalty and market penetration.

Inquire here to explore industry-specific data

@ https://www.databridgemarketresearch.com/inquire-before-buying?dbmr=global-injection-molding-machine-market

Emerging Opportunities

Emerging opportunities in the injection molding machine market are tied to global industrial trends:

Electrification and Lightweight Materials: As industries prioritize sustainability and efficiency, demand for electric and hybrid machines capable of processing advanced lightweight polymers and composite materials is expanding.

Additive-Molding Integration: Combining injection molding with additive manufacturing techniques (such as mold inserts made via 3D printing) facilitates rapid prototyping and reduced tooling costs—attractive to sectors with shorter product lifecycles.

Localized Production and Reshoring: Supply chain disruptions have motivated manufacturers in North America and Europe to reshore production facilities, increasing domestic demand for high-quality injection molding machines and skilled operator training.

Regional Analysis

Asia-Pacific leads the global injection molding machine market due to robust manufacturing bases in China, Japan, South Korea, and India. High industrial output, expanding automotive and electronics manufacturing, and government support for advanced machinery adoption drive regional dominance.

North America and Europe maintain significant market positions due to strong automotive production, regulatory emphasis on manufacturing efficiency, and the early adoption of automation technologies. Investments in smart factories and digital transformation initiatives further support market growth in these regions.

Latin America and Middle East & Africa are emerging as growth areas, supported by industrial diversification, infrastructure development, and increased foreign direct investments in manufacturing sectors.

Frequently Asked Questions (FAQs)

What is an injection molding machine?

Injection molding machines are industrial devices that melt and inject polymer resins into molds under high pressure to produce precision plastic parts.

Which technology type is gaining traction?

Electric injection molding machines are increasingly adopted for their energy efficiency, precision, and lower operational noise compared to hydraulic systems.

What industries use injection molding machines?

Automotive, electronics, packaging, medical devices, and consumer goods are key end-use sectors.

Which region dominates the market?

Asia-Pacific leads the market, driven by high industrial activity and manufacturing capacity.

Access the Full Report

Access the full “Injection Molding Machine Market” Report here

@ https://www.databridgemarketresearch.com/checkout/buy/global-injection-molding-machine-market/compare-licence

For More Reports

About Us

Data Bridge is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company’s aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

Contact:

Data Bridge Market Research Private Ltd.

3665 Kingsway — Suite 300

Vancouver BC V5R 5W2

Canada

+1 614 591 3140 (US)

+44 845 154 9652 (UK)

Email: Sales@databridgemarketresearch.com

Website: https://www.databridgemarketresearch.com