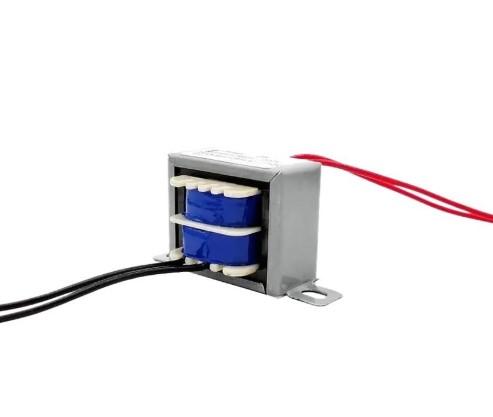

Why Choose an EI Transformer Factory for Reliable Power Solutions

The role of an EI Transformer Factory in modern industry has become increasingly significant as companies search for reliable electrical solutions to support diverse applications. These facilities focus on designing and producing transformers that contribute to stable power performance, ensuring that equipment functions smoothly in both commercial and industrial environments.

One of the defining aspects of such a factory is its emphasis on precision. Transformers are not just electrical components; they serve as a bridge between energy sources and devices that require controlled voltage levels. By ensuring consistent output, manufacturers help businesses reduce operational risks and maintain productivity across various systems.

In many industries, safety and compliance are critical considerations. Factories engaged in transformer production often adhere to recognized standards that prioritize reliable insulation, controlled heat management, and stable electrical performance. These measures not only extend the lifespan of transformers but also safeguard the systems they are integrated into, reducing the chance of unexpected downtime.

Another important factor is adaptability. Modern production facilities understand that clients operate in diverse fields, including automation, telecommunications, manufacturing, and renewable energy. To meet these needs, transformer factories apply processes that allow for flexibility in design and customization. Whether used in heavy-duty machinery or sensitive control equipment, transformers must match the requirements of their intended environment.

Efficiency also plays a vital role. In today's competitive marketplace, businesses seek solutions that balance cost-effectiveness with quality. Factories committed to sustainable manufacturing methods focus on minimizing waste, optimizing material usage, and integrating practices that align with environmental responsibility. These steps not only reduce production costs but also support broader goals of eco-friendly development.

Customer collaboration further enhances the value of these facilities. Open communication between manufacturers and clients helps ensure that specifications are met accurately. This cooperative approach allows the development of transformers that fulfill both immediate technical needs and long-term operational goals, making the factory a trusted partner rather than just a supplier.

Maintenance considerations cannot be overlooked. Transformers produced with durable materials and careful engineering reduce the likelihood of frequent servicing. Still, access to support, technical guidance, and replacement parts is important for companies investing in these products. A well-structured after-sales framework ensures that clients can rely on their equipment without unnecessary delays.

In addition, innovation continues to influence transformer manufacturing. As industries evolve and demand for automation grows, factories are incorporating advanced techniques and testing methods to deliver consistent and safe results. This progressive mindset ensures that transformer technology remains relevant and beneficial across future applications.

Ultimately, the presence of a professional transformer factory highlights the importance of dependable electrical infrastructure in modern operations. Businesses benefit not only from reliable components but also from the expertise and long-term value that such facilities provide.

For more information, please visit https://www.nbcbdz.com/product/