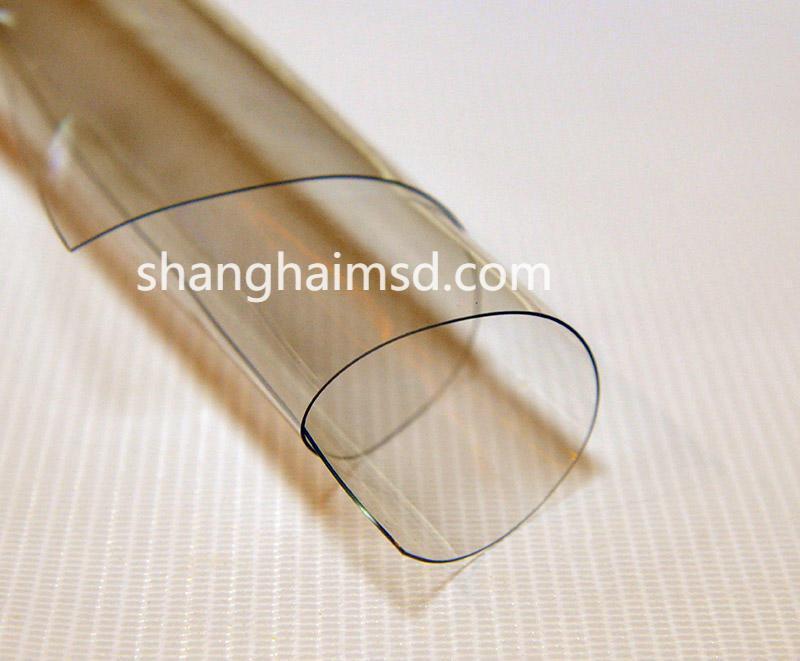

Choosing the Right Transparent Material for Visual Impact

PVC Super Clear Film is a high-quality, versatile material known for its exceptional transparency and superior clarity, making it ideal for a variety of applications. Produced using advanced techniques, this film has gained popularity in industries requiring both aesthetics and durability. Shanghai MSD is a key player in the production and supply of PVC Super Clear Film, offering products that meet the highest standards of quality and performance. This article delves into the material properties, processing methods, and main applications of this film, as well as its testing standards.

PVC Super Clear Film is made from polyvinyl chloride (PVC), a thermoplastic polymer that offers several benefits, including excellent clarity, chemical resistance, and flexibility. The film is typically transparent, allowing up to 90% light transmission, making it a highly desirable option in situations where visibility and optical clarity are essential. The unique formulation of the material allows for high tensile strength, preventing tearing or puncturing even under physical stress.

Furthermore, this film exhibits excellent resistance to aging, UV radiation, and moisture, making it ideal for both indoor and outdoor use. Its chemical resistance allows it to withstand exposure to oils, greases, and mild acids, while its smooth surface contributes to easy cleaning and maintenance. The combination of these properties makes it suitable for a wide range of applications, from packaging and signage to automotive and medical sectors.

The production of PVC Super Clear Film involves several sophisticated processes to ensure that the film meets the required standards of quality. Initially, raw PVC is combined with stabilizers, plasticizers, and other additives to achieve the desired properties. The film is then extruded using a cast extrusion process, in which the PVC mixture is heated and forced through a die to form a thin, uniform sheet.

The film can be further processed through calendaring or other mechanical techniques to improve its optical clarity and surface smoothness. This is essential for applications where visual quality is paramount. Depending on the intended use, the PVC Super Clear Film may be coated with additional layers for extra durability, such as UV-resistant coatings or anti-fog treatments. Shanghai MSD employs state-of-the-art technology and strict quality control measures to ensure that their products are free from defects and meet the industry’s highest standards.

One of the main applications of PVC Super Clear Film is in the packaging industry. Its high transparency makes it ideal for retail packaging, where product visibility is crucial. It is commonly used in packaging for food, electronics, and cosmetics, as it provides an attractive and protective barrier that allows consumers to see the product clearly without opening the package.

Additionally, this film is widely used in the signage and advertising sectors. Its ability to maintain clarity over time, even when exposed to outdoor elements, makes it an excellent choice for outdoor displays and billboards. The film's resistance to UV radiation ensures that it won’t discolor or degrade quickly, preserving the quality and appearance of the signage.

In the automotive industry, PVC Super Clear Film is used in protective covers, window films, and interior decorations. Its ability to resist scratches and maintain optical clarity makes it ideal for use in vehicle windows and displays. Furthermore, it is often used for protective packaging of automobile parts and electronics.

The medical sector also benefits from this film, particularly in the production of medical packaging and equipment covers. Its biocompatibility and resistance to chemicals make it a safe option for packaging pharmaceuticals and medical devices, where contamination and degradation are major concerns.

To ensure that PVC Super Clear Film meets the required specifications, various tests are performed throughout the manufacturing process. These include tests for tensile strength, elongation, UV resistance, and clarity. Tensile strength tests determine the film’s ability to withstand force without breaking, while elongation tests assess its flexibility. UV resistance testing ensures that the film can maintain its optical properties and prevent yellowing or degradation when exposed to sunlight for extended periods.

Clarity and transparency are also rigorously tested to ensure that the film provides the desired level of visibility. The film is subjected to optical testing using specialized equipment that measures light transmission and clarity. In addition, Shanghai MSD ensures that their PVC Super Clear Film products undergo rigorous quality control, with each batch being inspected to meet international standards for durability, safety, and performance.

PVC Super Clear Film is an advanced, versatile material with a wide range of applications across various industries. From packaging and signage to automotive and medical uses, this high-performance film offers excellent transparency, durability, and chemical resistance. Shanghai MSD’s high-quality products meet stringent testing standards, making them a reliable choice for applications requiring exceptional clarity and performance.For more information about PVC Super Clear Film and its applications, visit https://www.shanghaimsd.com/news/industry-news/pvc-super-clear-film-the-ultimate-transparent-solution-for-versatile.html .